Today, world production of this iron-carbon alloy reaches 1.6 billion tons with Italy ranking second in the EU in quantity. Corrosion resistance is the feature that favored the spread of stainless.

It is one of the most common materials in the world invented by man. In 2017 alone, according to the World Steel Association, 1.6 billion tons of it were produced, up more than 5 percent over the previous year.

And it is at the center of a very hot topic, that of Trump-imposed tariffs that threaten to upset some global balances.

We are talking aboutsteel, a material with countless uses and types, among which stainless steel certainly stands out, whose properties are now widely recognized.

SOME NUMBERS AND THE ISSUE OF TARIFFS

Let’s start with the numbers.

China is the country in the world with the highest steel production: it alone produces half of it, and exactly 830 billion tons. They are followed by Japan, with 104 billion tons, and India with 101 billion. The U.S. ranks fourth with 81 billion tons.

European Union reaches 168 billion tons, up 4 percent over 2016. Italy is the second largest country in the EU by production (24 billion tons) after Germany (43 billion).

Analyzing this data, it is easy to understand the concern of the EU leadership and member states regarding Trump’s decision to place the 25 percent duty on imported steel from abroad.

Trump, a staunch nationalist, argues that the free trade system harms America and leverages national security motives. He also claims that unfair trade practices have hurt industries in the sector.

In other words, the president denounces the fact that the U.S., vis-à-vis many countries, imports more than it exports; even though this practice results in benefits to the U.S. economy because it makes steel available at low cost for industries.

The EU and Japan in recent weeks have negotiated with the president to be excluded from these penalties, leveraging their longstanding partnership while threatening tariffs on other types of products.

Everyone agrees that a trade war benefits no one; yet the negotiation remains particularly difficult and Trump aspires to obtain alternative measures from other states. For the time being, the EU has won a brief exemption until May 1.

THE PROPERTIES OF STEEL

Technically , steel is an alloy of iron and carbon: the percentage of the latter element must be less than 1.7 percent, otherwise it is called cast iron.

This material is characterized by its high mechanical properties of stress resistance, which, however, depends on its composition.

Carbon is what determines them: the greater the presence of this element, the more they improve a number of characteristics:

- the yield strength, which is the value of the stress at which a material begins to deform plastically, changing from reversible elastic behavior to irreversible deformation;

- the breaking load, which is the unit stress, originating from external stresses, that causes failure of a given material;

- Hardness, that is, resistance to scratching.

At the same time, however, as the amount of carbon increases, they decrease:

- elongation, that is, deformation as a result of temperature or particular mechanical stresses;

- striation, which is the reduction in cross-sectional area that a body undergoing tensile stress undergoes;

- resilience, which is the resistance to failure under dynamic stress.

The usual classification of steel divides it into two categories:

- unalloyed steels, which contain varying amounts of carbon (up to 1 percent) and low amounts of other elements such as manganese and silicon;

- alloy steels that contain other alloying elements such as nickel and titanium.

Today there are more than 3,500 types of steel with different chemical, physical and environmental properties.

STAINLESS STEEL.

It is a special steel, patented in 1872 by two Englishmen, with a high amount of chromium (usually 18%, but can be as high as 35%) and nickel (typically 8%, but can be as high as 35%).

The advantage of stainless steel is that it does not oxidize in the air and is resistant to aggressive agents, and thus has a long service life. Unlike ordinary steels, in fact, it forms a thin oxide layer that becomes a protective patina and blocks the oxidation process, preventing rusting.

Therefore, stainless steel is used widely in a variety of industries: automotive, mechanical, transportation, food, household, plant engineering, and medical just to name a few.

In food, in particular, it is the ideal material due to its high hygienic performance, resistance to corrosion, high temperatures and alteration by chemicals and acids .

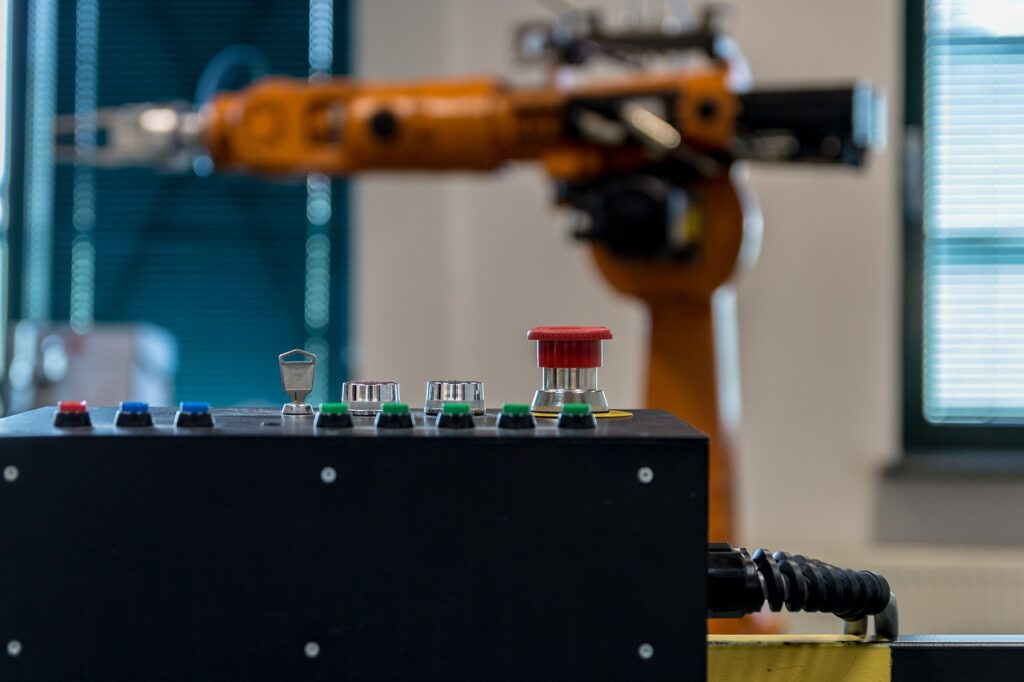

EiQ Industrial, in accordance with current regulations, uses European-sourced AISI 304L or AISI 316L stainless steel for the production of certified switchboards. These are two types of austenitic stainless steel alloys, that is, with high percentages of alloying elements.

In AISI 316L stainless steel, chromium is present between 16 and 18 percent, nickel between 11 and 14 percent, and molybdenum up to 3 percent. In AISI 304 stainless steel, there is between 18 and 20 percent chromium and between 8 and 11 percent nickel

However, EiQ Industrial is able to offer switchboards in steels other than standard steels thanks to the design team that can study customized solutions as needed.